Gas-sensing capsule takes another big step from lab to commercialisation

An ingestible gas-sensing capsule that provides real-time insights into gut health has moved closer to market with RMIT University transferring IP ownership to medical device company Atmo Biosciences.

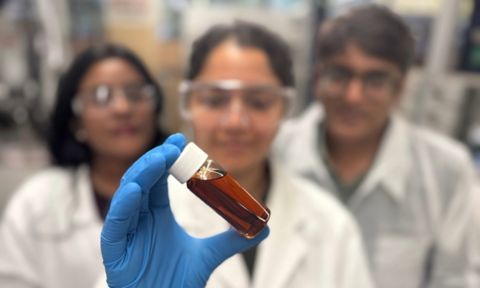

Aussie tech helps make bio-oils for greener industrial applications

Australian technology developed at RMIT University could enable more sustainable and cheaper production of bio-oils to replace petroleum-based products in electronic, construction and automotive applications.

Australia’s visual and craft arts sector likened to the gig economy in new report

A new study into the incomes and career lifecycles of Australia’s visual arts and craft workers has revealed conditions are deteriorating.

Researchers hope to improve disaster evacuations in Maui

A new study is collecting stories about evacuation from those affected by the Maui wildfires, in the hope of better preparing for future disasters.