Water expert joins RMIT Europe

Drawing on extensive expertise in water resource science from Melbourne, Australia, RMIT’s Professor Vincent Pettigrove is set to collaborate with RMIT Europe’s staff and industry partners over the next six months, particularly through his involvement in a research project aimed at improving coastal resilience throughout Europe.

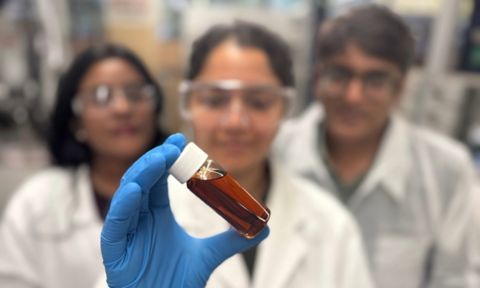

Aussie tech helps make bio-oils for greener industrial applications

Australian technology developed at RMIT University could enable more sustainable and cheaper production of bio-oils to replace petroleum-based products in electronic, construction and automotive applications.

RMIT Centre for Applied Quantum Technologies launches during International Year of Quantum

This week, RMIT Centre for Applied Quantum Technologies (RAQT) was launched by the University.